Accessory Stock Management

Manage accessory stock at the variation level, track stock entries, and monitor status transitions in Fleet Master.

Overview

Accessory Stock Management in Fleet Master is designed to support real-world warehousing and distribution use cases for accessories, with focus on:

- Variation-level control

- Granular stock entries

- Lifecycle status tracking

- Chargeable vs Non-Chargeable handling

- Assignment and return logging

- Full stock flow auditability

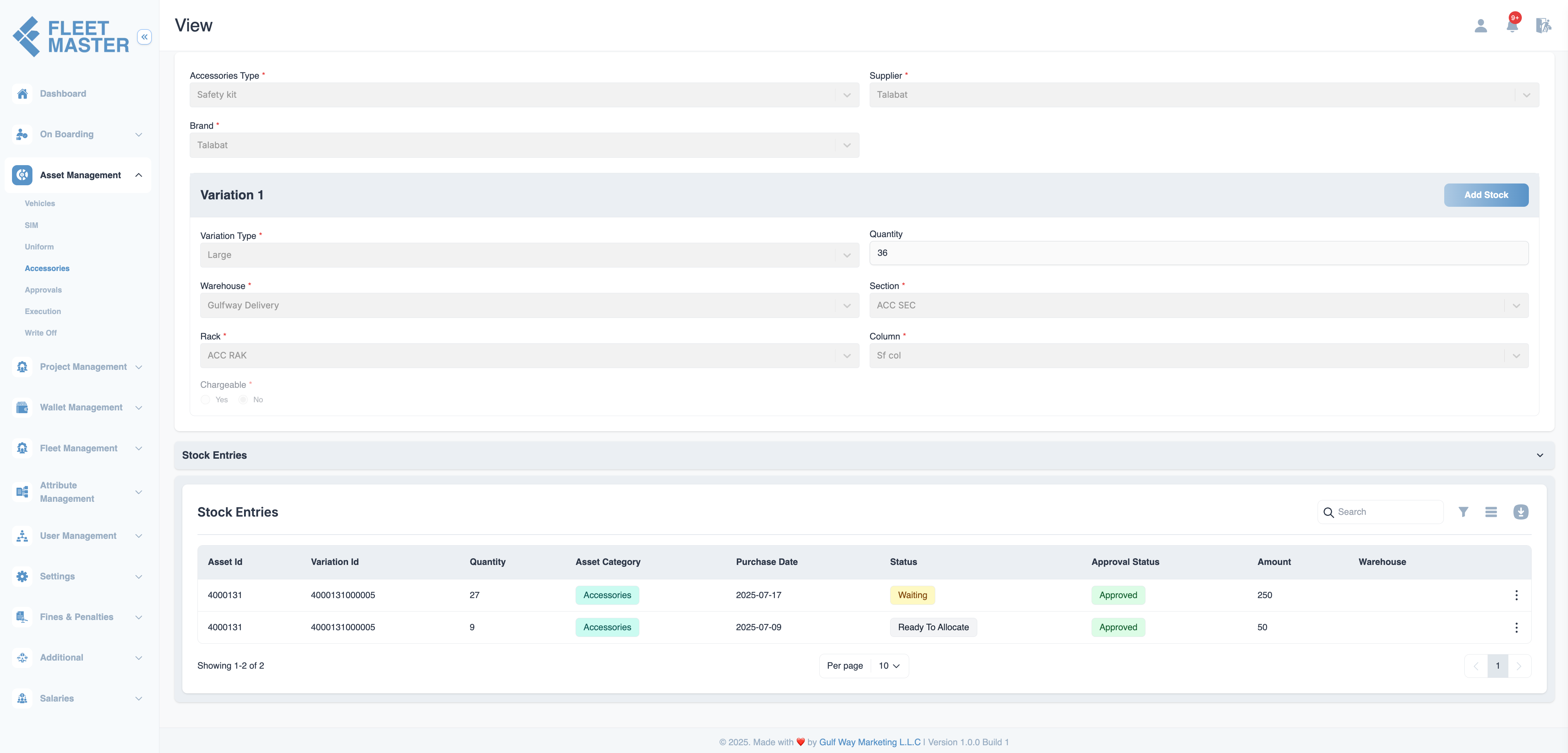

Stock by Variation

Accessories in Fleet Master are created with variations (e.g., "Helmet – M – Full Face", "RFID Card – Type A"). Each variation holds its own independent stock records.

Tip:

This separation allows accurate quantity tracking, cost reporting, and variation-specific analytics.

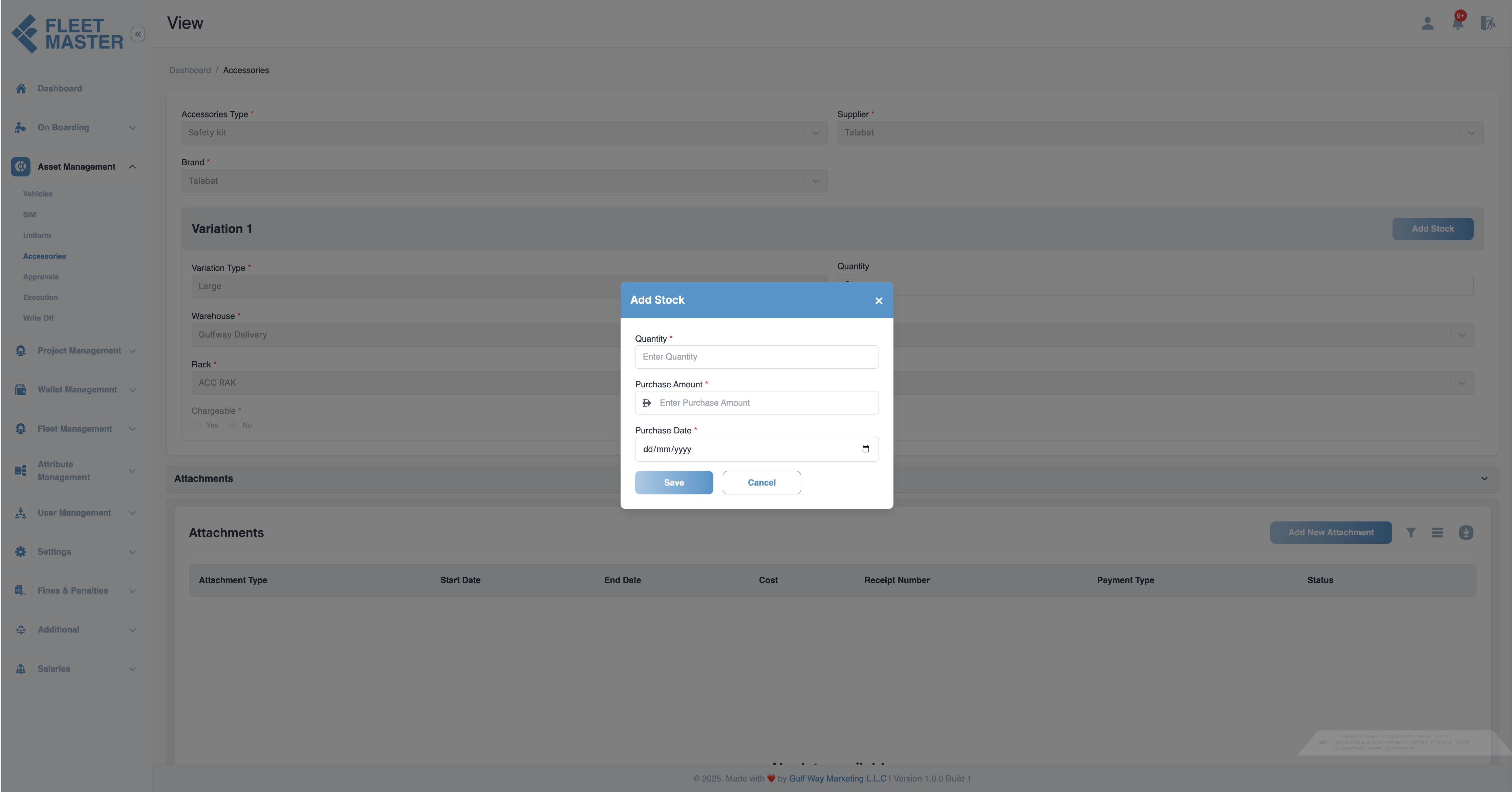

Adding Stock

You can add multiple stock entries under a variation.

When adding a new stock entry, specify:

- Quantity

- Purchase Price (optional)

- Supplier / Vendor (optional)

- Location:

- Warehouse

- Section

- Rack

- Supporting Documents (invoice, receipts, etc.)

- Initial Lifecycle Status (default:

Waiting) - Chargeable: Yes / No

- If "Yes", input:

- Markup % (e.g., 15%)

- VAT % (e.g., 5%)

- If "Yes", input:

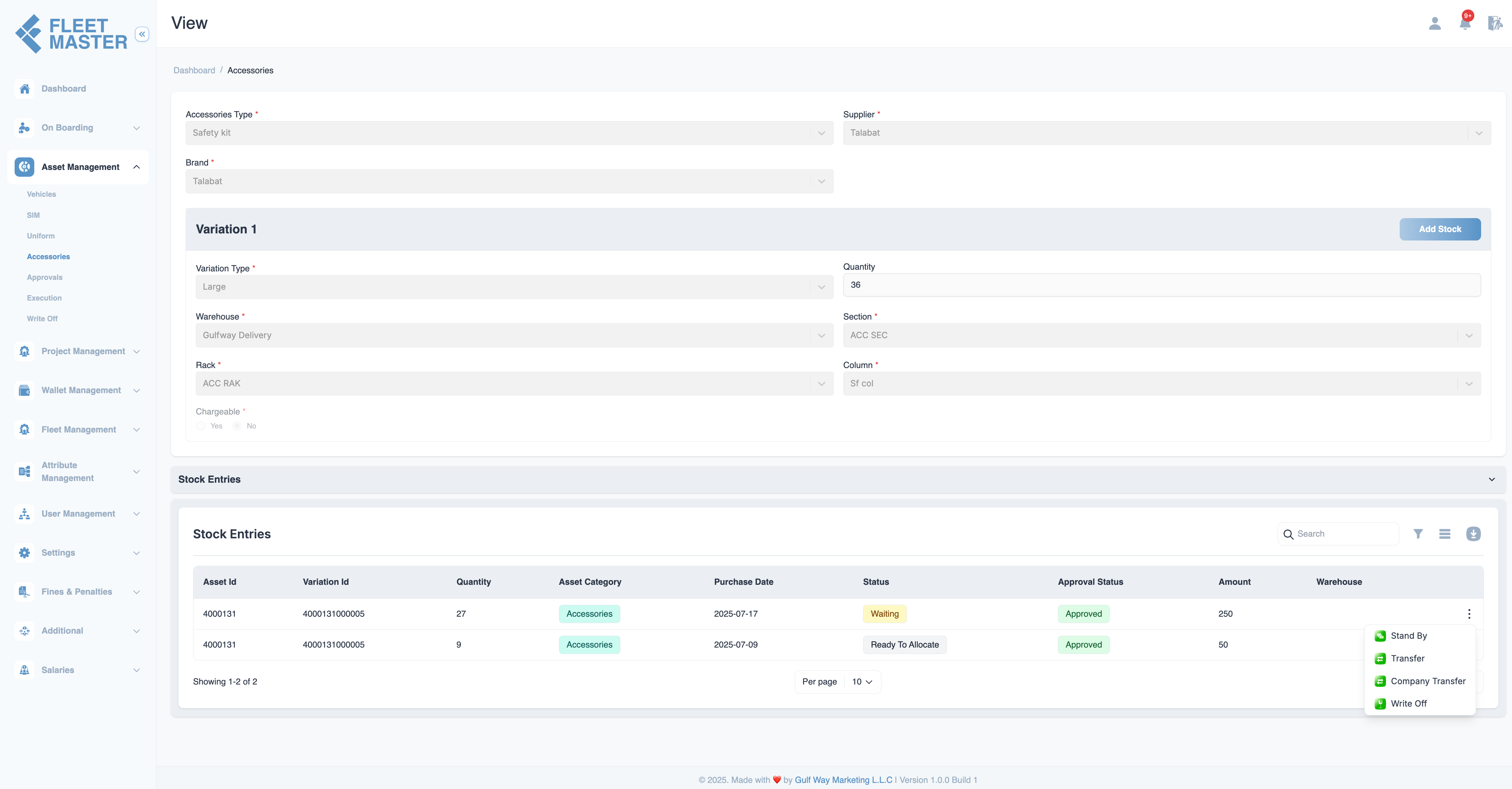

Stock Lifecycle Status

Each stock entry has a lifecycle status to represent its current usability:

| Status | Description |

|---|---|

Waiting | Newly added, pending verification |

Standby | Verified and stored but not available for allocation |

Ready to Allocate | Cleared for assignment |

Assigned | Temporarily reserved/linked to a fleet |

Executed | Officially handed over to fleet (stock marked as consumed) |

Returned | Item returned by fleet — becomes new Incoming in stock entry log |

Written-Off | Damaged/expired/unusable stock marked as removed from usable stock |

Lifecycle movement can be manual or automated based on business rules.

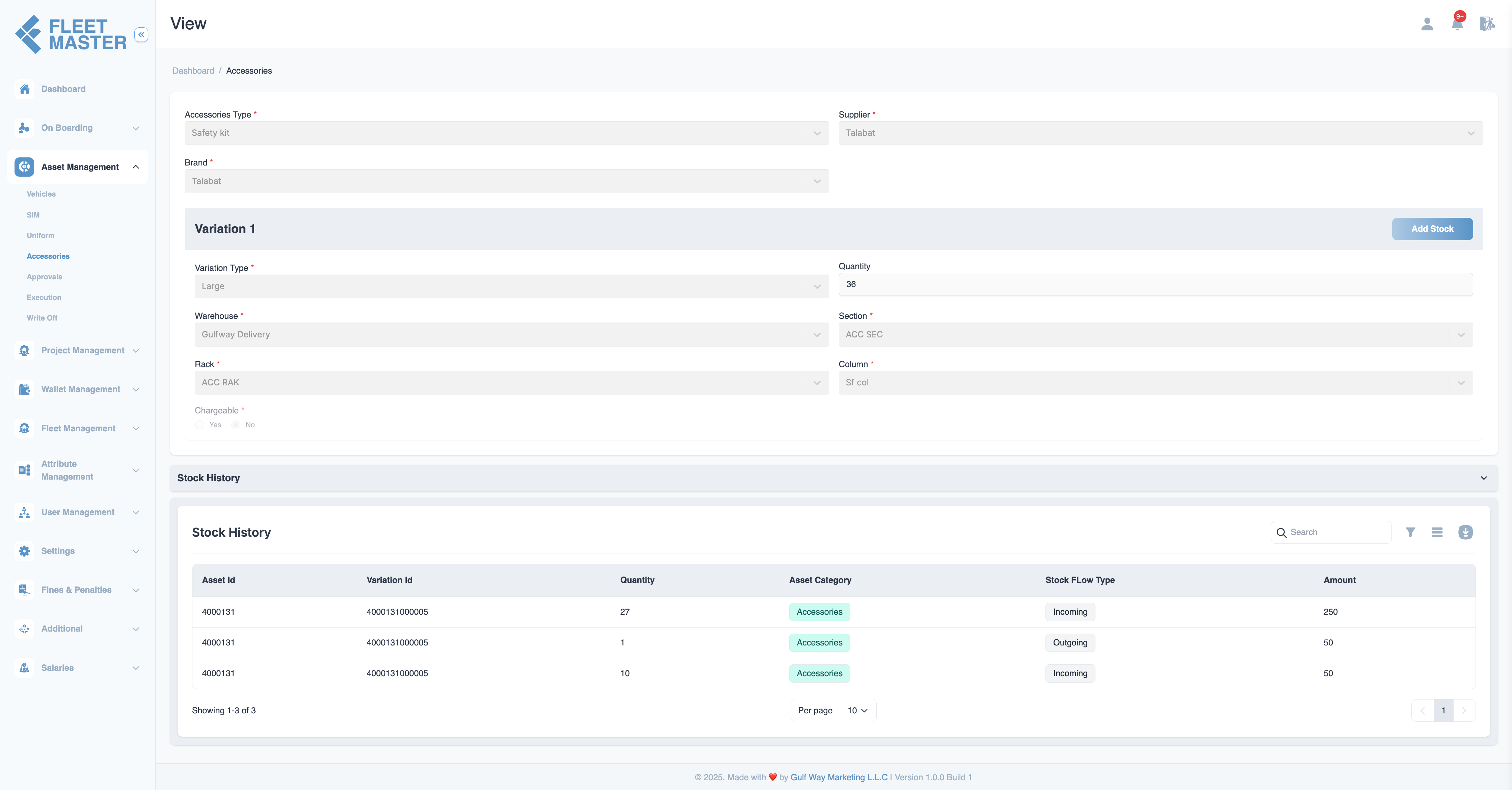

Movement Tracking

The system records every movement into a Stock Movement Log:

Types of Movement

- Incoming

- New purchase entries

- Returned accessories

- Outgoing

- Assigned to fleet

- Written off or lost

Movement Record Includes:

- Movement Type (Incoming / Outgoing)

- Source / Destination (Warehouse / Fleet)

- Quantity moved

- Linked Variation

- Date of movement

- Reference file (optional)

- Transaction type (Assignment, Return, Write-off, etc.)

Assignment to Fleet

When assigning an accessory to a fleet:

- The system checks if enough quantity is available in

Ready to Allocate. - Quantity is deducted from available stock.

- If Chargeable, system calculates:

- Selling Price = Base + Markup

- Tax = Selling Price * VAT%

- A Withdraw Transaction is logged.

- The item enters the

Assignedstatus. - Once the fleet confirms (with signature, optionally), it moves to

Executed.

Return Flow

If a fleet returns an item:

- The item is inspected and marked as reusable or not.

- If reusable:

- Enters as

Incoming - Status is reset to

StandbyorReady to Allocate - A Return Transaction is recorded

- Enters as

- If damaged or expired:

- It is moved to

Written-Off

- It is moved to

Chargeable Stock Logic

If Chargeable = YES

- System requires:

- Markup % input

- VAT % input

- During assignment:

- System calculates the total cost to fleet

- Withdrawal + deposit transaction is created

- Fleet will see the amount in salary deduction / expense report

- Admin panel allows editing the markup/VAT before final approval

If Chargeable = NO

- System skips price calculations

- Still logs the assignment for tracking

- No financial transactions triggered

Audit & History

Each variation has a stock movement history:

- Filter by: Type (incoming/outgoing), Status, Fleet, Date

- Export to Excel/PDF

- View linked attachments (invoice, return slip)

- Track who added, edited, or confirmed each stock entry

Example Scenario

- Admin adds 50 helmets (Full Face – M) with markup 10%, VAT 5%.

- Status =

Waiting→ Moves toReady to Allocate. - 2 helmets are assigned to fleet A.

- 1 helmet is returned after use (good condition).

- That helmet re-enters as

Incoming, status =Standby. - 3 helmets are damaged in warehouse, marked

Written-Off.

Fleet Master reflects:

- 44 helmets remaining (

Ready to Allocate) - 1 helmet (

Standby) - 2 helmets (

Executed) - 3 helmets (

Written-Off)

Note:

All stock activities are transparent and permission-controlled to ensure accountability and traceability.