Uniform Lifecycle Transitions

Track uniforms through their lifecycle in Fleet Master — from stock entry by variation, to quantity-based assignments, returns, transfers, and write-offs.

Overview

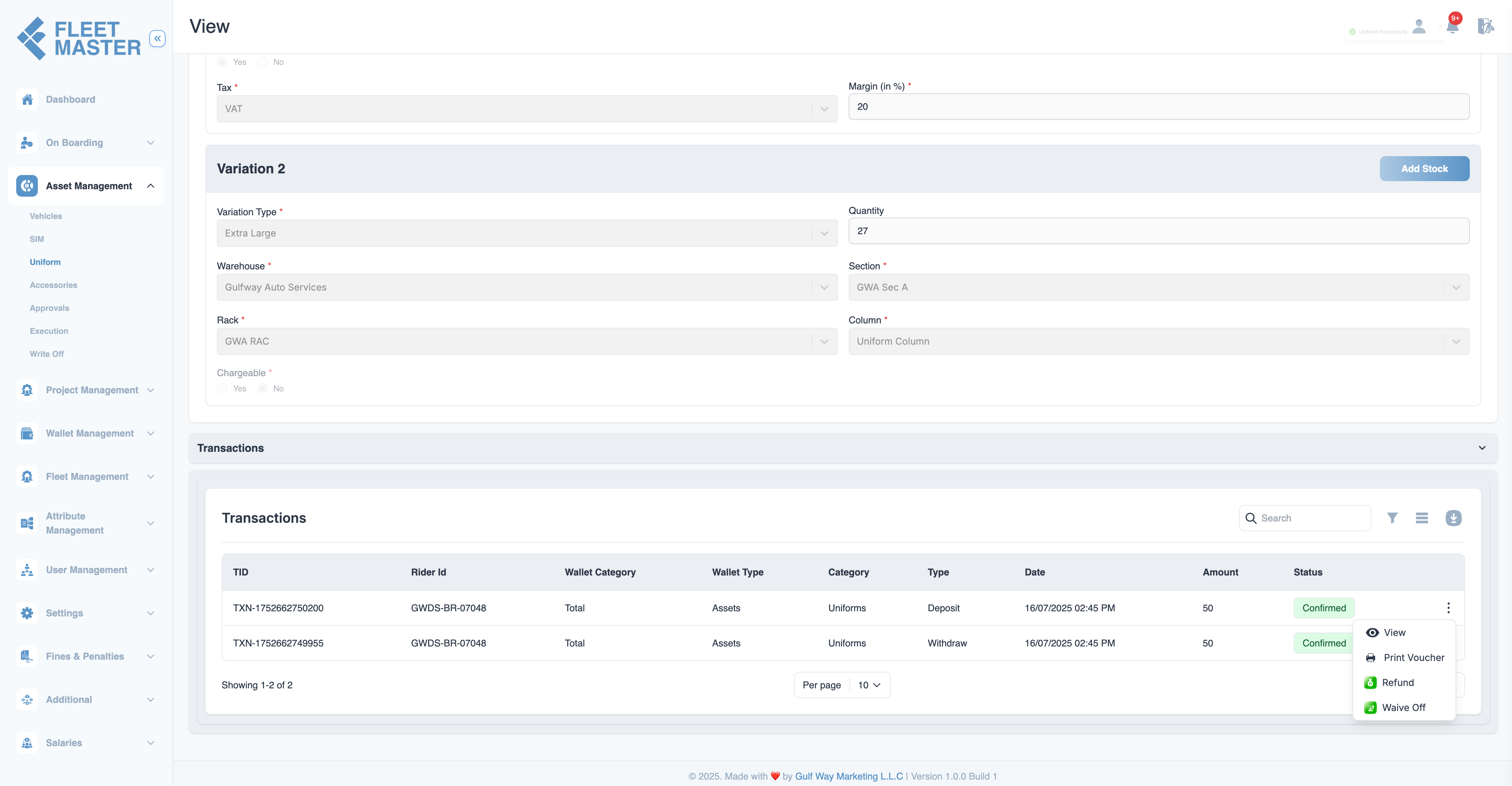

Fleet Master manages Uniforms at the variation level, allowing detailed tracking of stock entries and lifecycle transitions. Unlike vehicles, uniforms are assigned in quantities, and each assignment is logged with transaction records. Variations may be chargeable or non-chargeable, and the system handles markup, VAT, and receipts automatically.

Core Concepts

Variation-Based Stock

Uniforms are grouped into variations (e.g., Shirt – Large, Jacket – Small). Each variation can hold multiple stock entries, and transitions are applied at the stock entry level.

Quantity-Based Assignment

Uniforms are assigned in quantities instead of one-to-one mappings. You can assign:

- Multiple items to one fleet

- Partial quantities from a stock entry

- Different variations in a single session

If the variation is chargeable, the system auto-generates:

- A withdraw transaction

- A deposit transaction

- A receipt document, upon confirmation

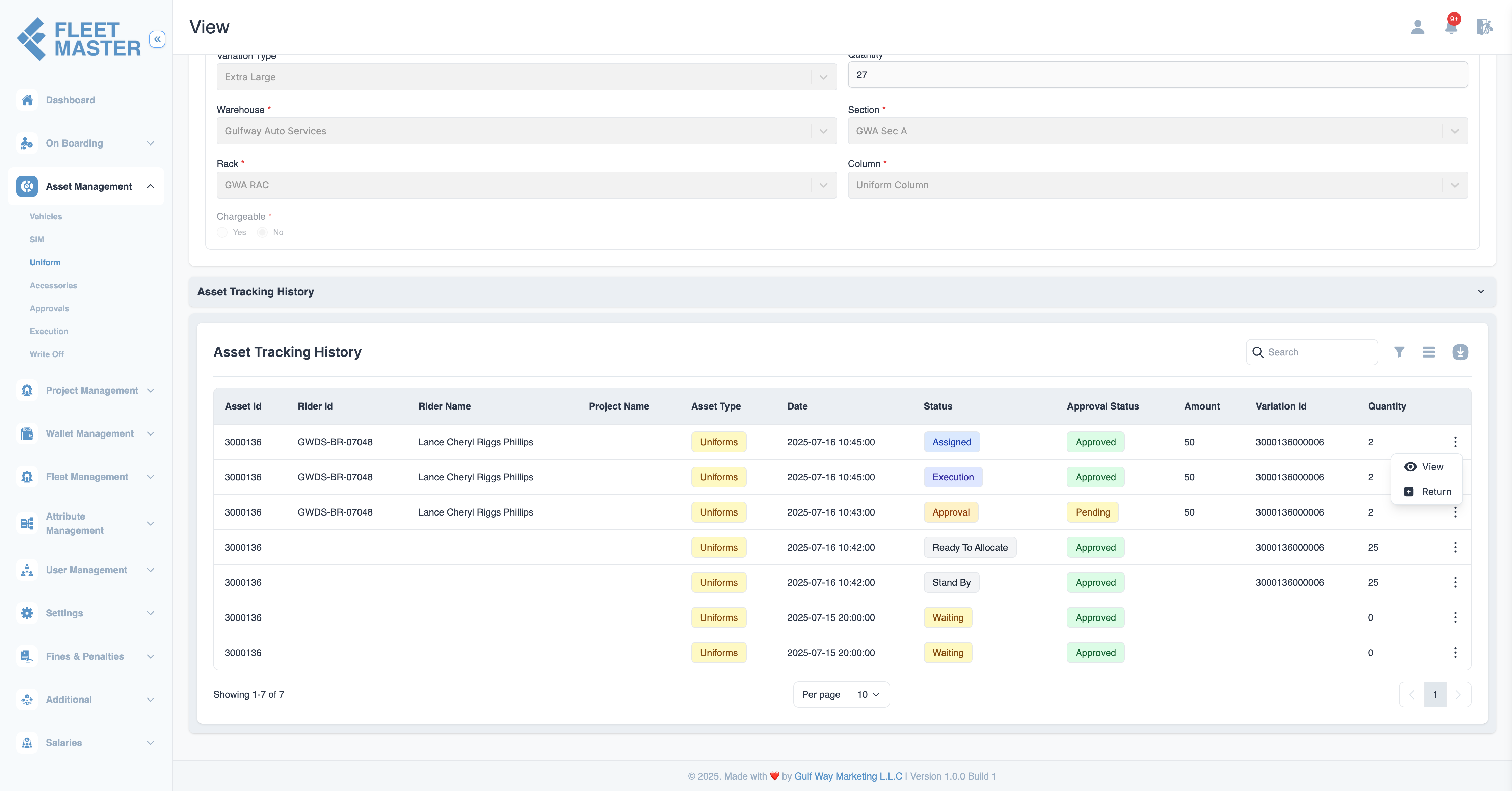

Lifecycle Statuses

| Status | Description |

|---|---|

| Waiting | Newly added stock, not validated |

| Standby | Verified but not yet ready for allocation |

| Ready to Allocate | Stock is available for assignment |

| Assigned | Uniforms are issued to a fleet |

| Returned | Items are returned to stock, quantity-wise |

| Transferred | Stock is moved across warehouses or companies |

| Write-Off Pending | Stock marked for decommissioning |

| Write-Off Approved | Finalized write-off after approval |

Transition Steps

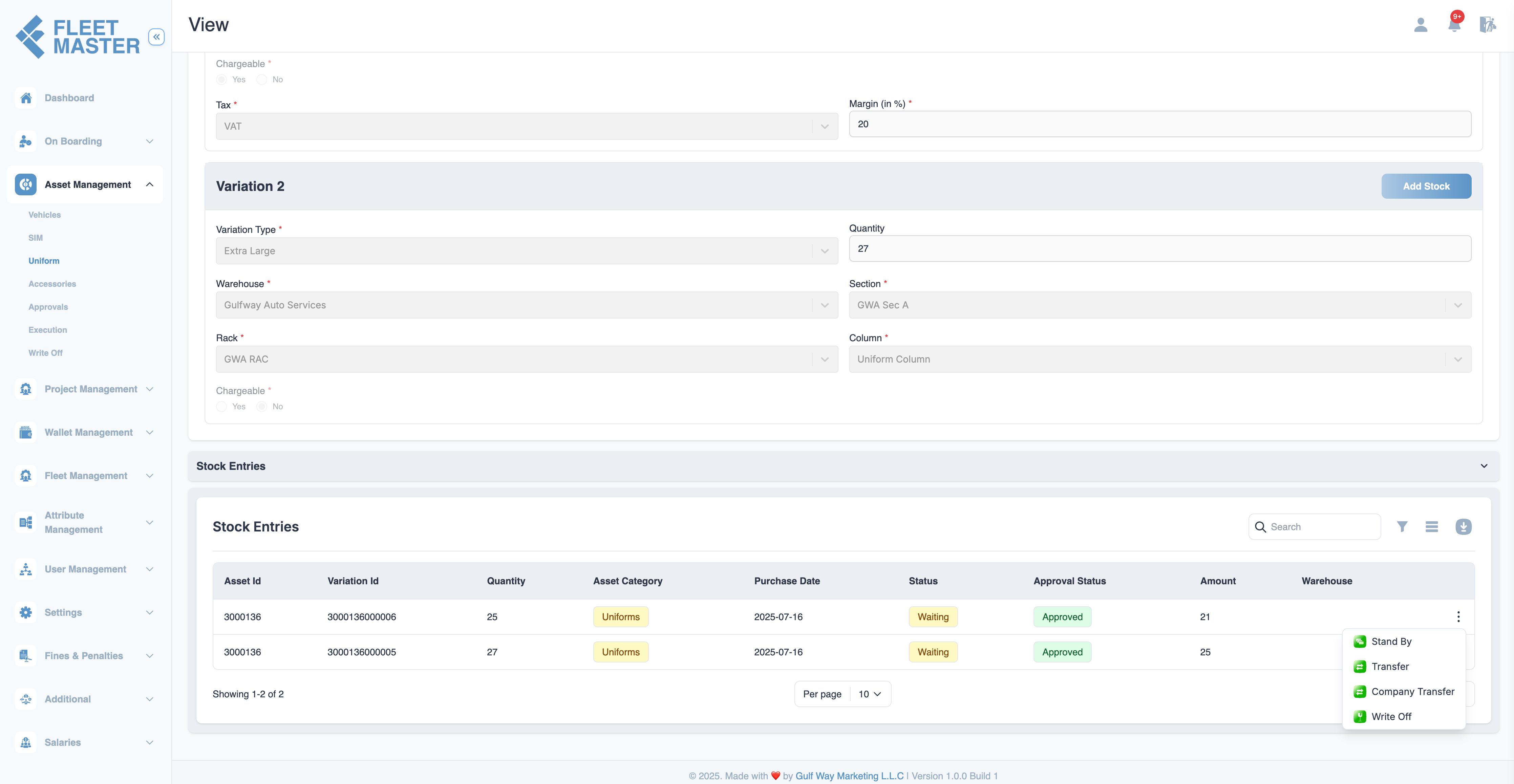

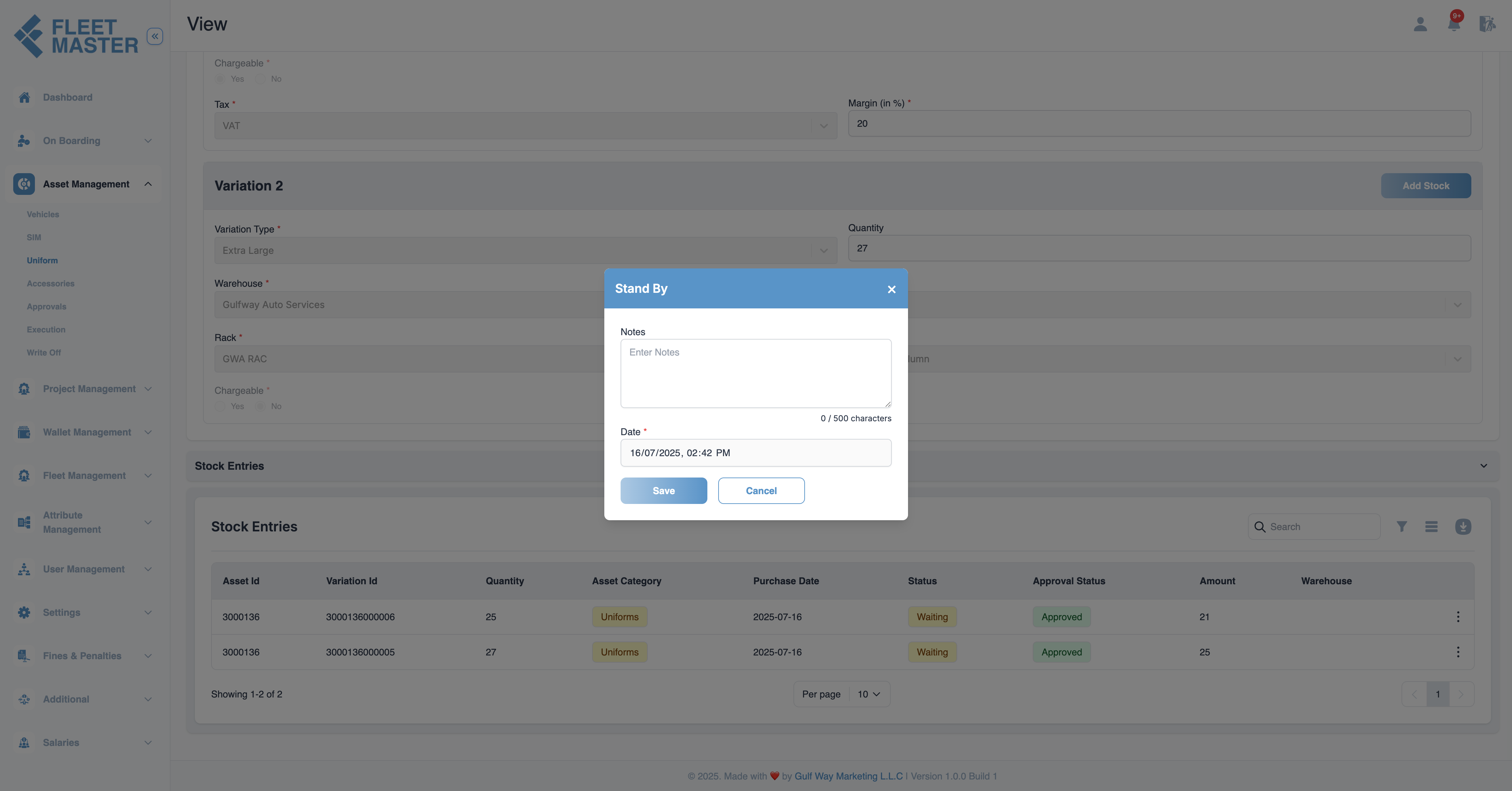

1. Waiting → Standby

| Field | Required |

|---|---|

| Validation Date | Yes |

| Notes | Optional |

Used when quality check or stock review is complete.

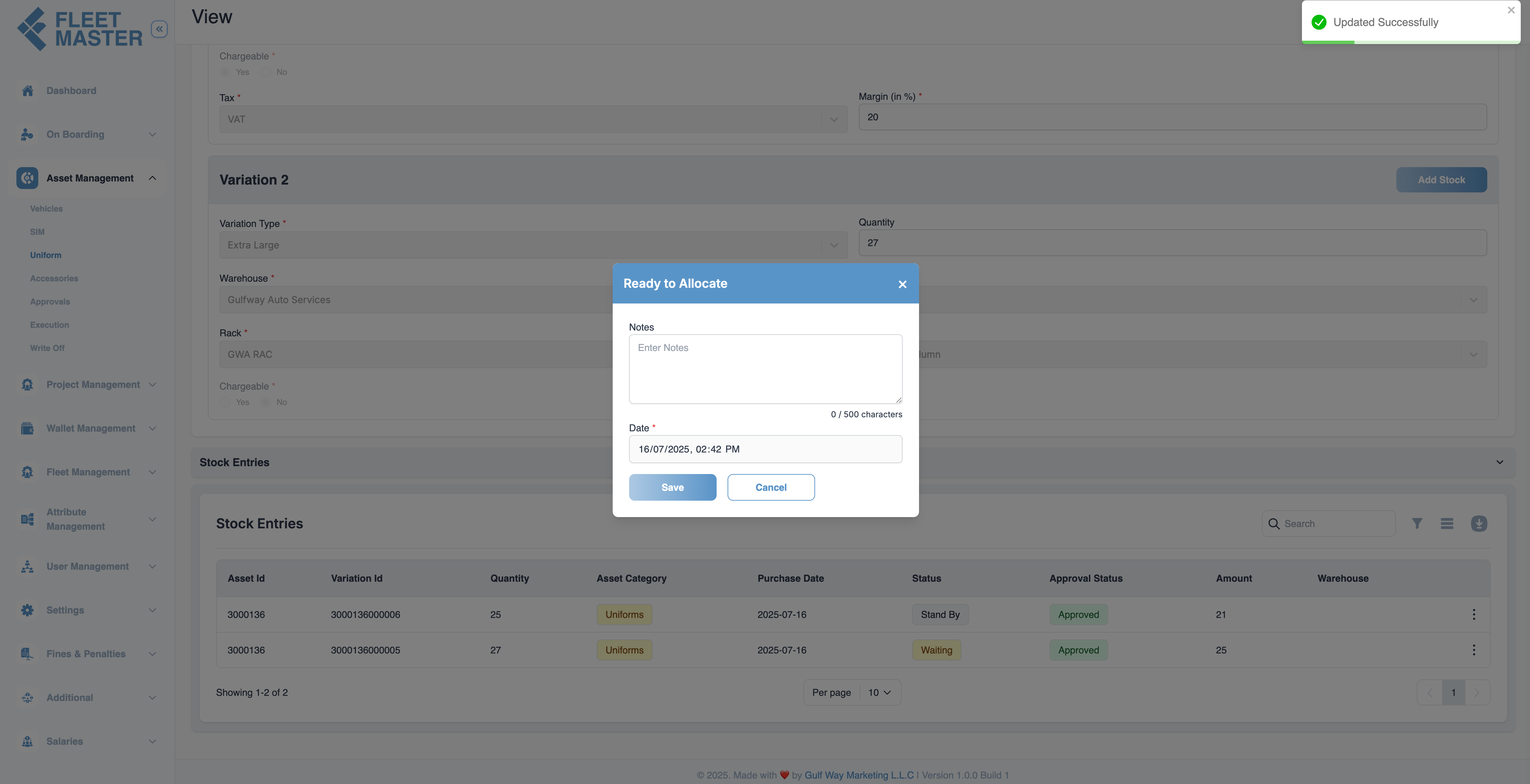

2. Standby → Ready to Allocate

| Field | Required |

|---|---|

| Validation Date | Yes |

| Notes | Optional |

Makes the uniform available for assignment.

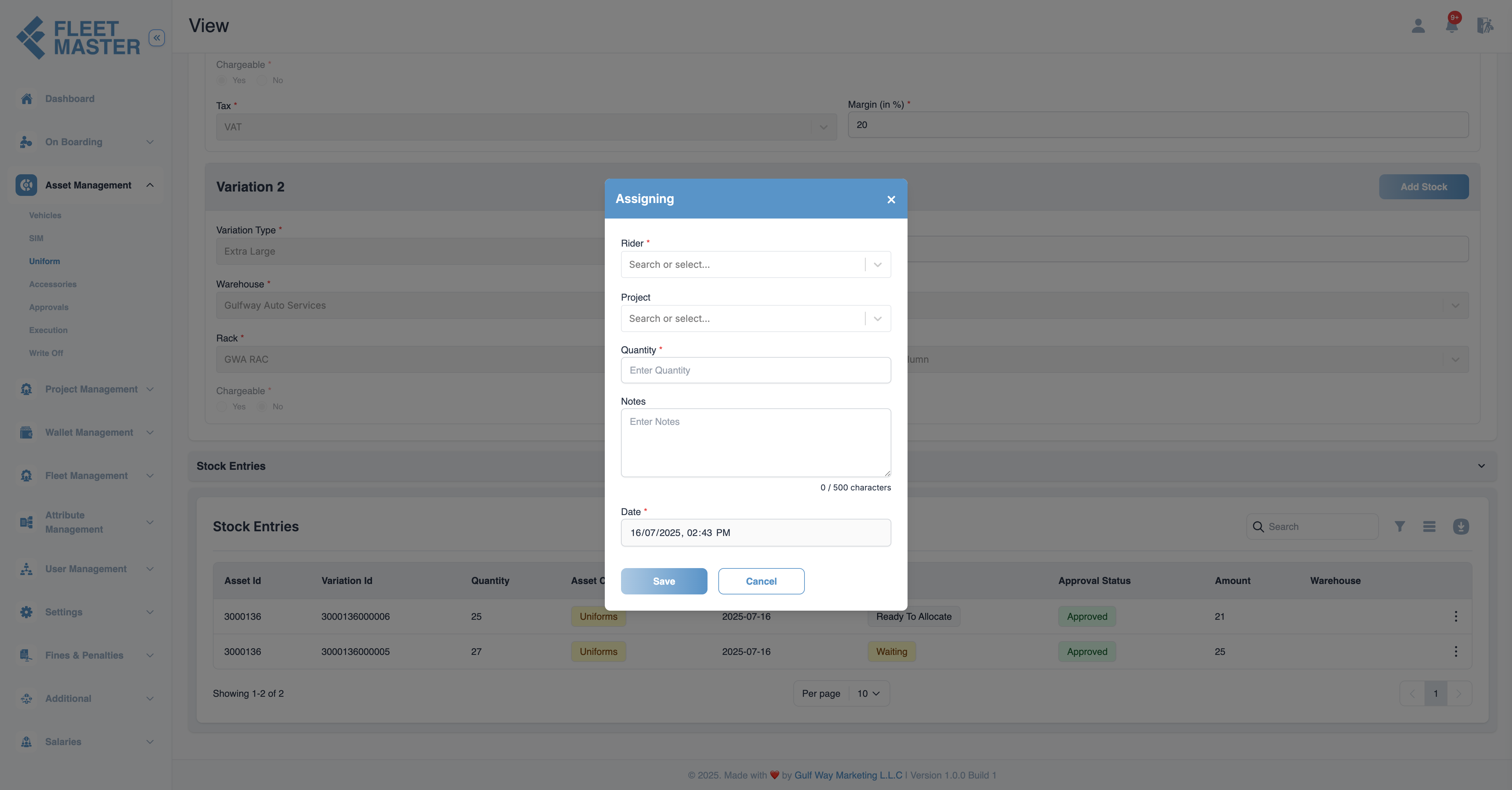

3. Ready to Allocate → Assigned (Quantity Based)

| Field | Required |

|---|---|

| Fleet | Yes |

| Quantity | Yes |

| Assignment Date | Yes |

| Project / Notes | Optional |

Note:

For chargeable uniforms, system generates:

- Withdraw Transaction

- Deposit Transaction

- Pending Receipt Assigned quantities are deducted from the selected stock entry. Partial quantities are supported.

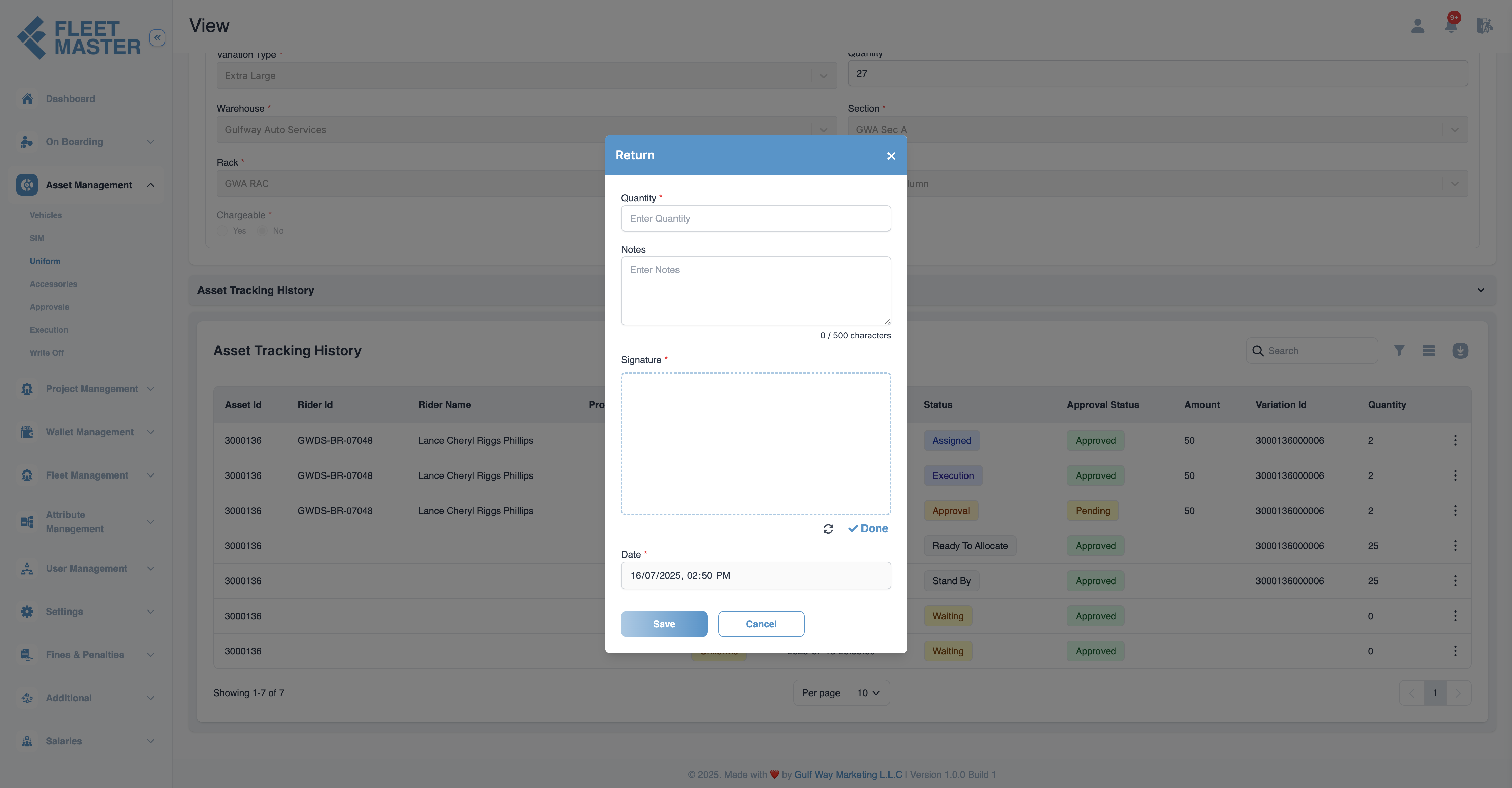

4. Assigned → Returned

| Field | Required |

|---|---|

| Return Date | Yes |

| Quantity | Yes |

| Condition | Optional |

| Notes | Optional |

Returned stock is tracked separately and may be:

- Revalidated and moved to Standby or

- Written off if damaged

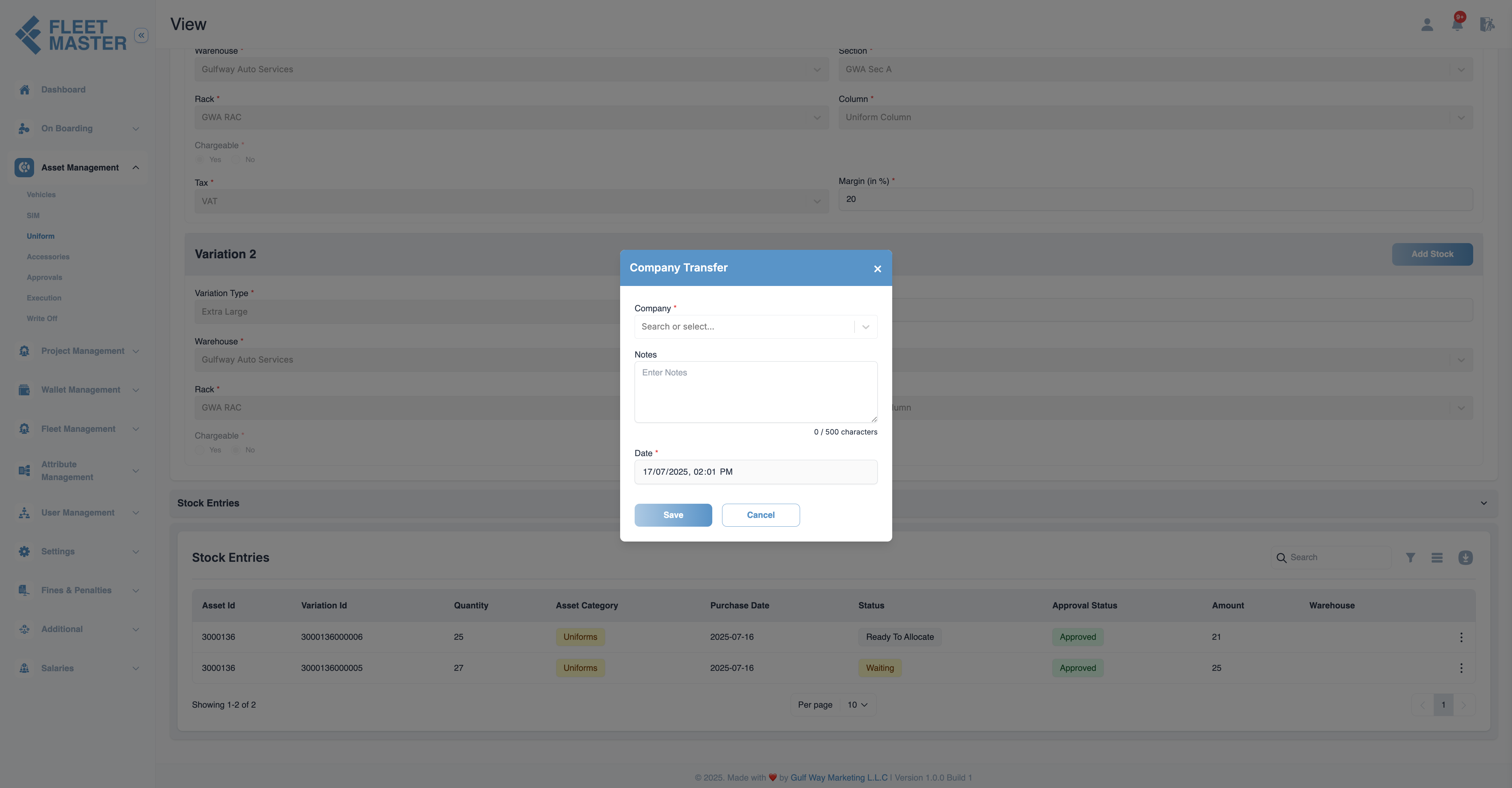

5. Company Transfer (Inter-location or Inter-company)

| Field | Required |

|---|---|

| New Company | Yes |

| Transfer Date | Yes |

| Notes | Optional |

Updates history of the stock entry.

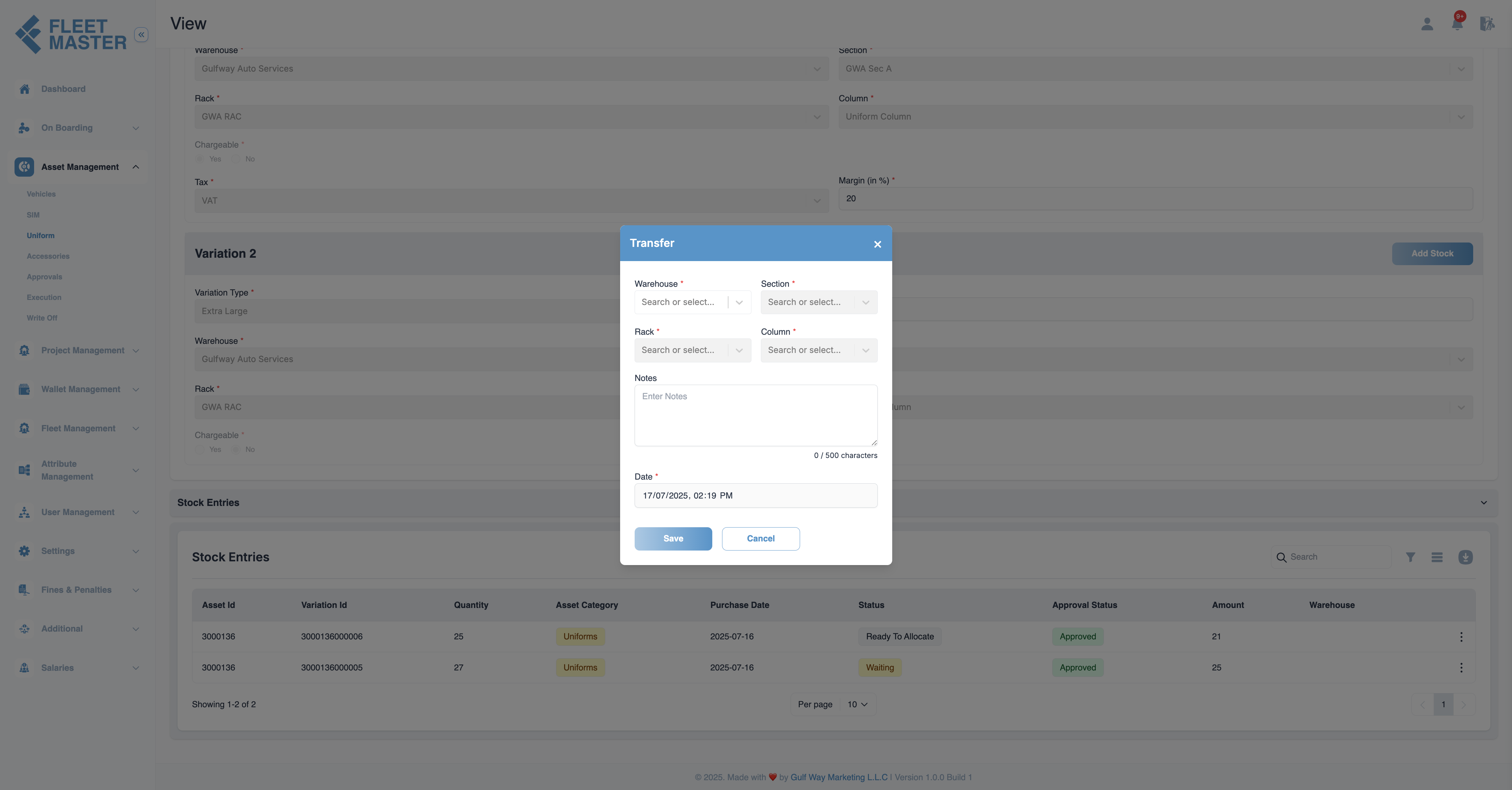

6. Transfer (Inter-location )

| Field | Required |

|---|---|

| Warehouse | Yes |

| Section | Yes |

| Rack | Yes |

| Column | Yes |

| Transfer Date | Yes |

| Notes | Optional |

Updates location of the stock entry.

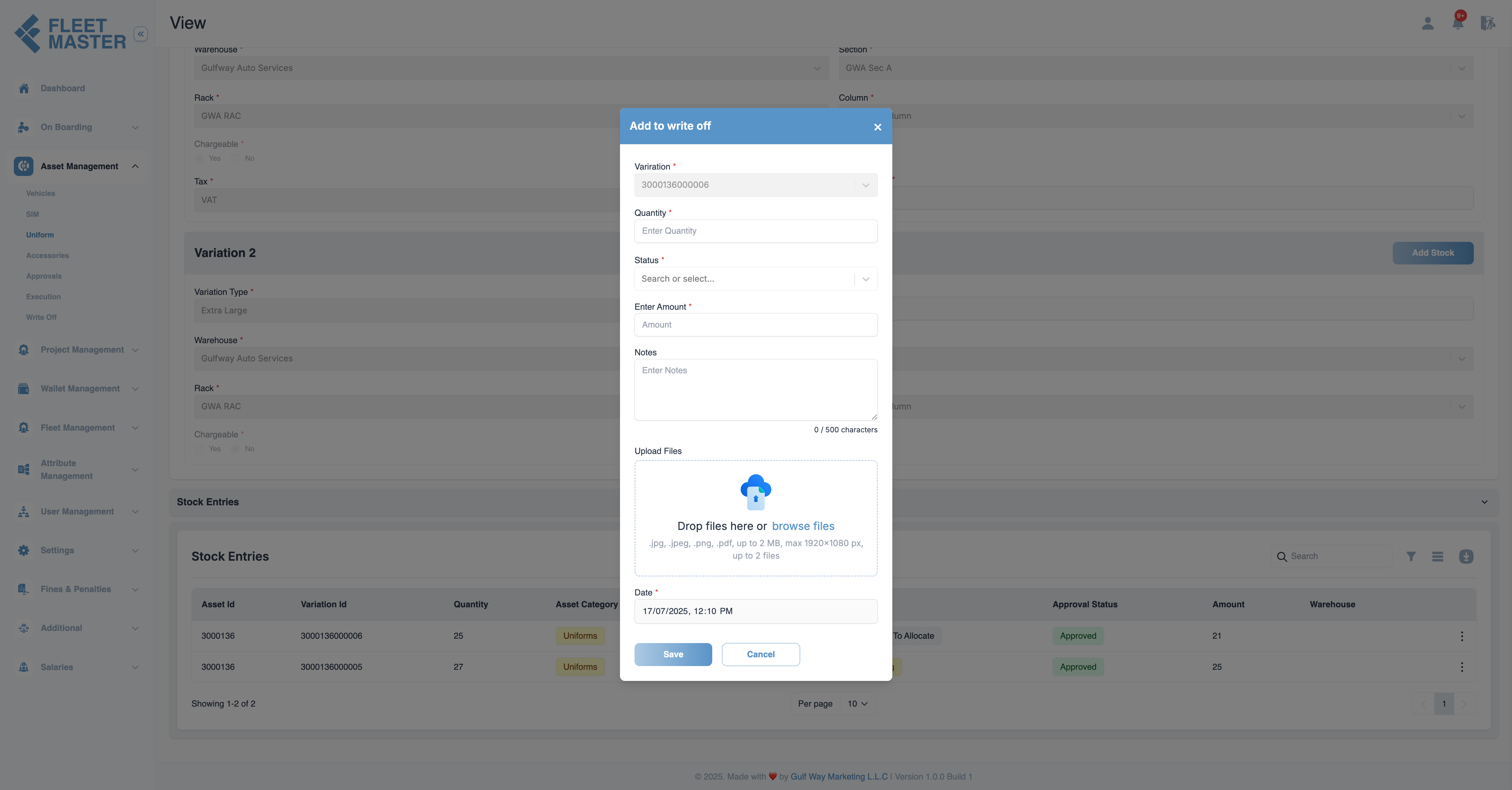

7. Write-Off Pending → Write-Off Approved

Pending

| Field | Required |

|---|---|

| Reason as status | Yes |

| Date | Yes |

| Quantity | Yes |

| Variation | Yes |

| Amount | Yes |

| Notes,files | Optional |

Approval

| Field | Required |

|---|---|

| Approval Decision | Yes |

Note:

Once approved, quantity is removed from stock and archived.

Summary Table

| From Status | To Status | Required Fields | Notes |

|---|---|---|---|

| Waiting | Standby | Validation Date | |

| Standby | Ready to Allocate | Ready Date | |

| Ready to Allocate | Assigned | Fleet, Quantity, Date, Variation, Chargeable | Auto-handles chargeable logic |

| Assigned | Returned | Quantity, Date | Returned stock re-enters lifecycle |

| Any Active Status | Transferred | Location, Date, Variation, Quantity | Supports partial transfers |

| Any Active Status | Write-Off Pending | Reason, Date, Quantity, Variation | |

| Write-Off Pending | Write-Off Approved | Approval Decision | Final archive of stock |

Chargeable Handling Workflow

| Field | Description |

|---|---|

| Is Chargeable | Boolean (per variation) |

| Markup % | Applied to base cost on assignment |

| VAT % | Added post-markup |

| Generated | Withdraw + Deposit + Receipt |

System Tip:

Uniforms marked as chargeable require finance confirmation before final receipt is generated.

Stock History in Variation View

Each uniform variation contains a full Stock History tab with:

- All status transitions

- Quantity movements

- Linked assignments and returns

- Related documents and notes

Best Practices

- Assign uniforms using the variation and quantity fields — not individually.

- Always validate entries before marking them Ready to Allocate.

- For chargeable uniforms, double-check markup/VAT configurations.

- Use Return workflow to recover uniforms and track usage.

- All transitions leave an auditable trail via stock history.