Vehicle Tracking

Manage and track the lifecycle of assets including assignment, return, warehouse mapping, fleet signatures, and document attachments. This section also covers asset write-off history and tracking in Fleet Master.

![]()

Overview

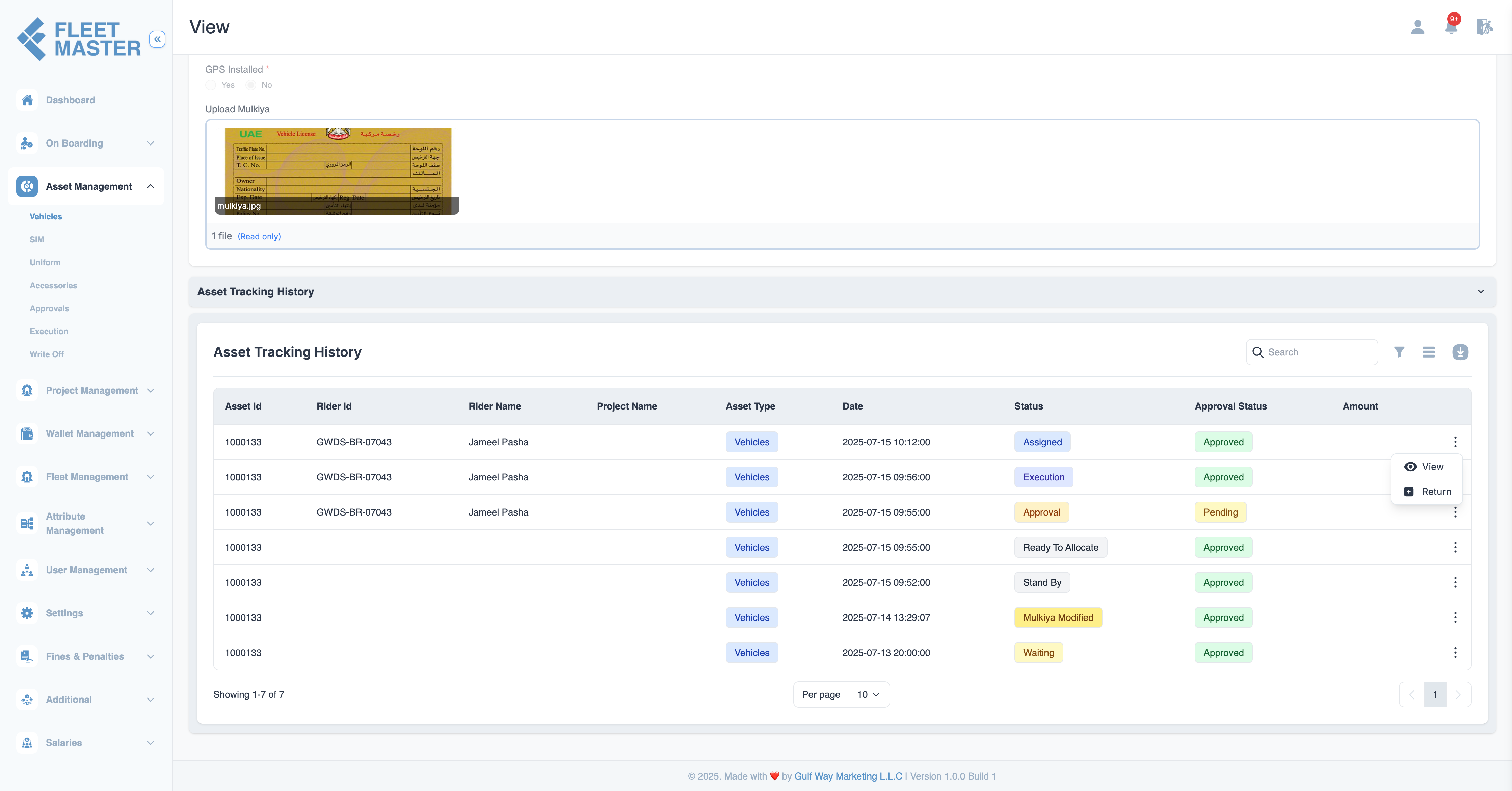

The Asset Tracking module in fleet master enables you to track the lifecycle of each asset, from assignment to return, including tracking historical data and storing related documents. It also offers a detailed view of warehouse mappings, fleet signatures, and write-off history, ensuring all assets are properly managed and accounted for.

Asset Assignment

When an asset is assigned to a fleet or project, the following details must be filled:

| Field | Description |

|---|---|

| Fleet | The assigned fleet's name or ID. (Required) |

| Assignment Date | The date the asset is assigned. (Required) |

| Warehouse | The warehouse location for the asset. (Required) |

| Rack | The rack where the asset is stored. (Required) |

| Section | The section within the warehouse. (Required) |

| Column | The column in which the asset is placed. (Required) |

| Fleet Signature | Digital or physical signature of the fleet. (Required) |

| Assignment Notes | Any special instructions or details. (Optional) |

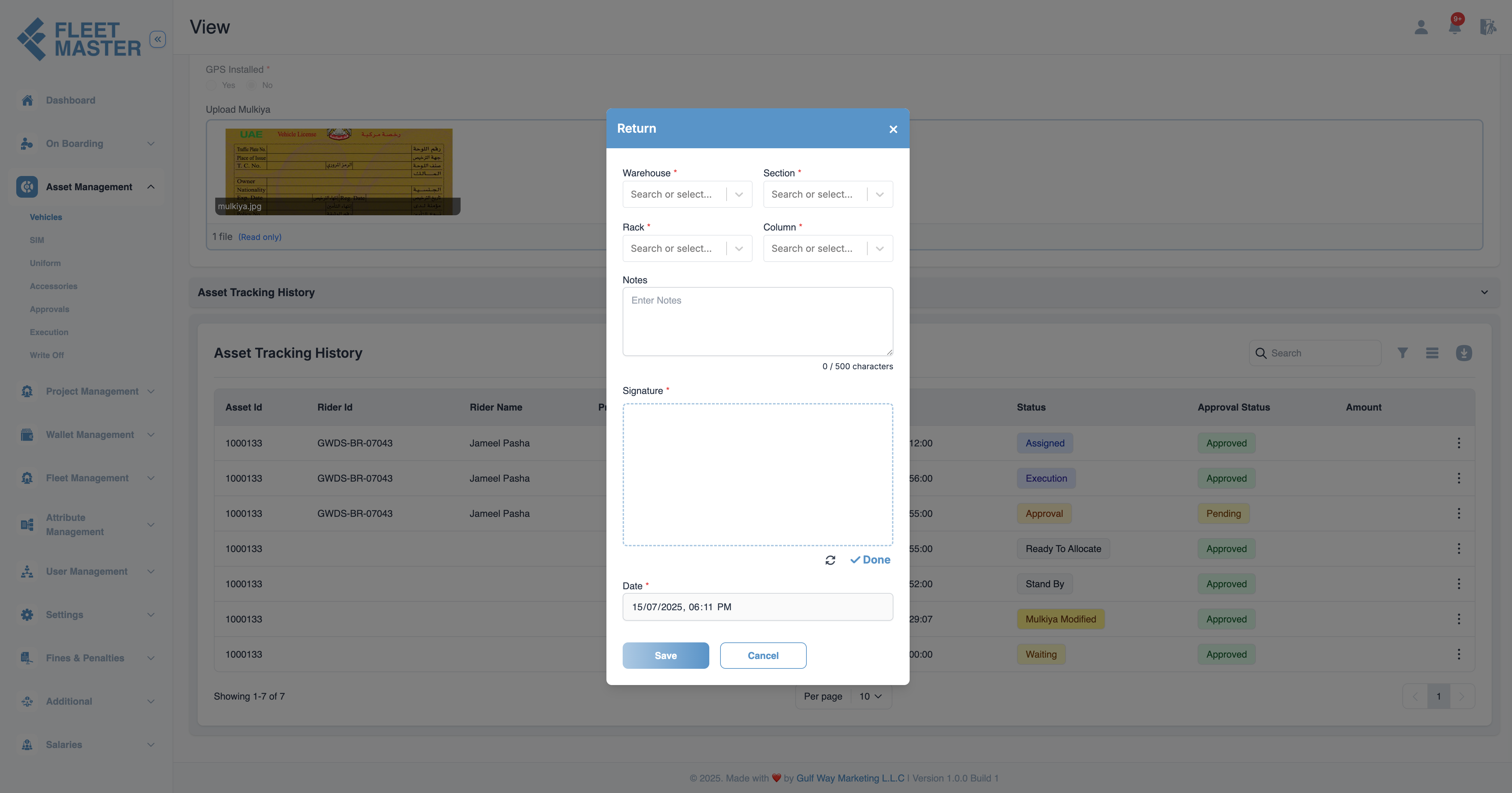

Asset Return

If the asset is returned, the following actions need to be taken:

| Field | Description |

|---|---|

| Return Date | The date the asset is returned. (Required) |

| Condition | Condition of the asset when returned (e.g., Good, Damaged). (Required) |

| Return Notes | Any special notes related to the return. (Optional) |

| Return Signature | Signature of the person accepting the return. (Required) |

Note:

Once the asset is returned, it will move to the Available status, ready to be reassigned or decommissioned.

Warehouse Mapping

Each asset is stored in a specific location within the warehouse. When assigning or tracking assets, the following warehouse details are captured:

| Field | Description |

|---|---|

| Warehouse | The storage warehouse where the asset is kept. (Required) |

| Rack | The rack within the warehouse where the asset is located. (Required) |

| Section | The section within the warehouse that houses the asset. (Required) |

| Column | The column where the asset is placed. (Required) |

Note:

Warehouse mapping ensures the proper location is recorded for easy retrieval and better asset management.

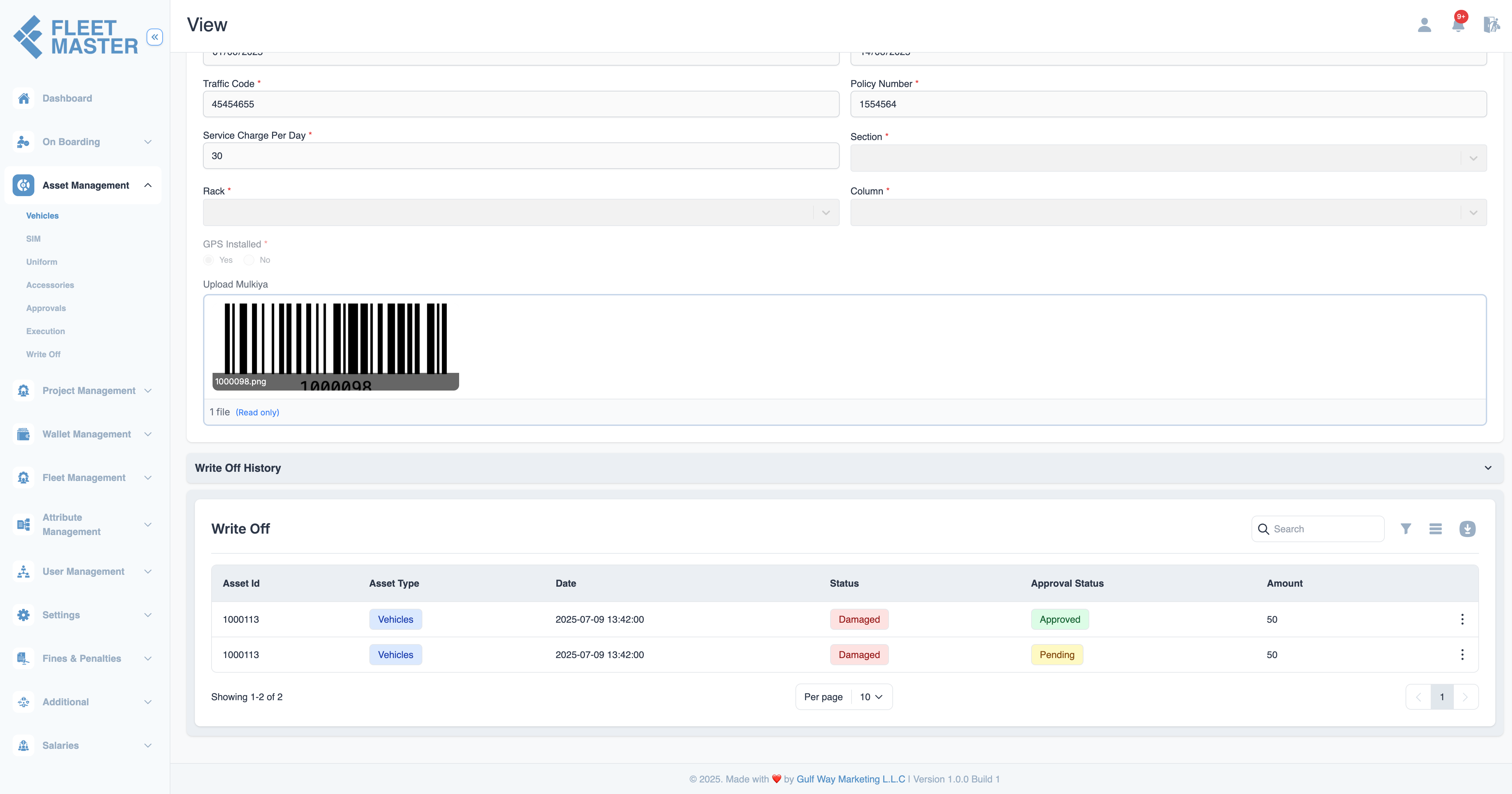

Write-Off History Tracking

The Write-Off History tracks when an asset is decommissioned, written off, or permanently removed from active use. The following fields capture important data:

| Field | Description |

|---|---|

| Write-Off Reason | The reason for the asset write-off (e.g., Sold, Damaged). (Required) |

| Write-Off Date | The date the asset was written off. (Required) |

| Approval Status | Status of the write-off (e.g., Pending, Approved). (Required) |

| Approval Date | The date the write-off was approved. (Required) |

| Notes | Any additional notes related to the write-off. (Optional) |

Note:

All write-offs are tracked with a full history for audit and compliance purposes.

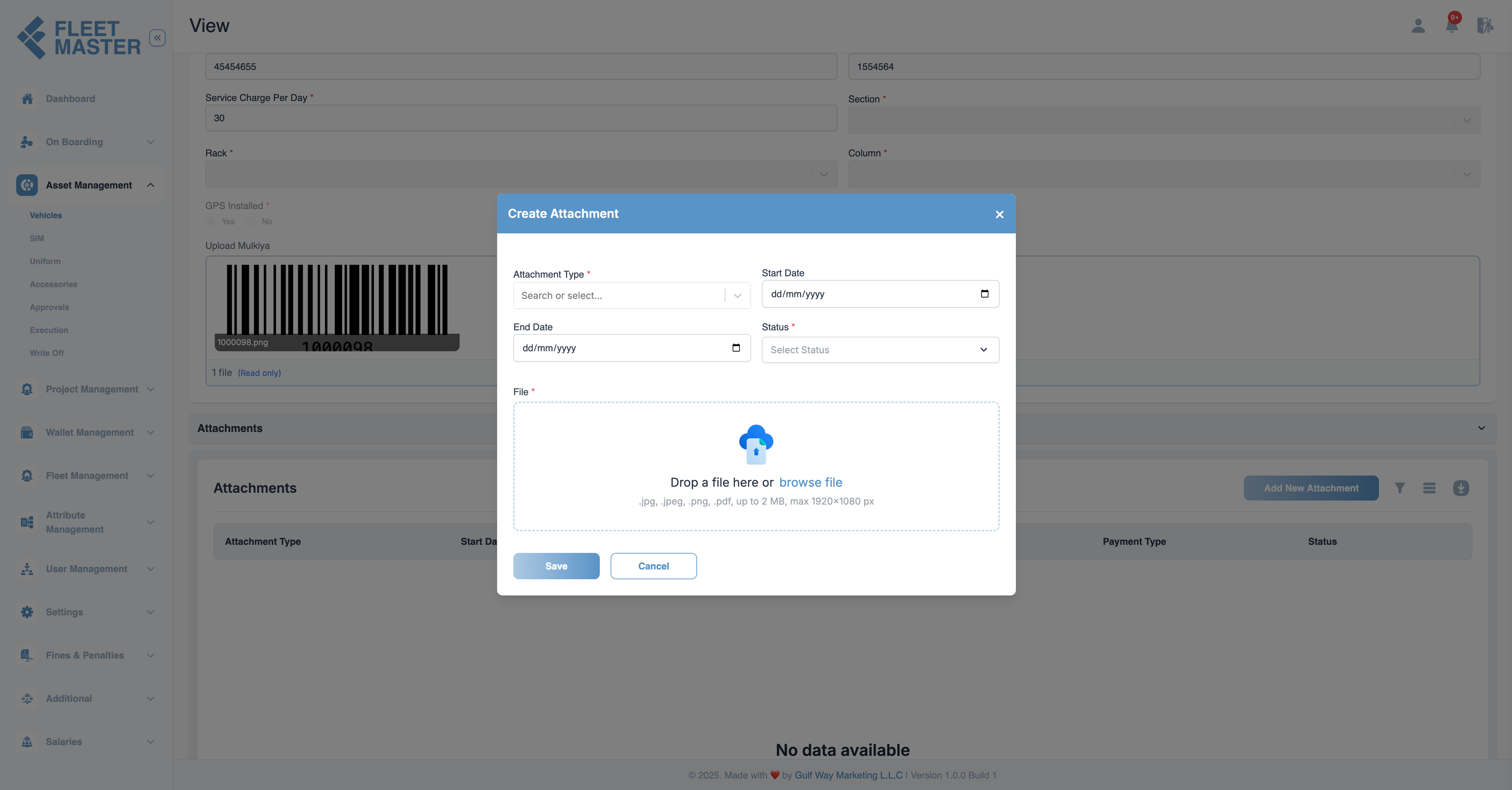

Attachments

The Attachments section allows you to upload related documents for each asset. These documents could include purchase receipts, maintenance logs, contract agreements, or any other relevant records. The following document types are supported:

| Document Type | Description |

|---|---|

| Purchase Receipt | Upload the purchase receipt or invoice. (Required) |

| Warranty Documents | Upload warranty information for the asset. (Optional) |

| Maintenance Logs | Upload maintenance logs or repair records. (Optional) |

| Contract Agreements | Upload any contracts associated with the asset. (Optional) |

| Write-Off Documents | Attach documents related to the write-off process. (Optional) |

| Condition Report | Attach any reports regarding asset condition (e.g., upon return or inspection). (Optional) |

Note:

All attachments are stored securely and can be referenced later for audits, inspections, or compliance checks.

Key Features

- Warehouse Mapping: Properly tracks asset storage locations across different warehouses, racks, sections, and columns.

- Asset Assignment & Return: Easily manage the assignment and return processes, including signatures and condition reports.

- Write-Off History: Track the full history of asset write-offs, ensuring complete audit trails.

- Attachments: Add and manage all related documents for each asset, improving organization and compliance.

Best Practices

- Complete Warehouse Mapping: Ensure all assets are properly mapped to their specific warehouse, rack, section, and column to avoid confusion and loss.

- Document Uploads: Always upload related documents such as purchase receipts, warranties, and maintenance logs for future reference.

- Write-Off Compliance: Ensure all write-offs are approved and tracked to maintain compliance with organizational policies.

- Return Process: Always document the condition of the asset upon return, including signatures, to prevent disputes and ensure proper tracking.